工業(yè)廠房車間除塵系統(tǒng)介紹

來源:http://68428.com.cn/ 發(fā)布時間:2023-10-22

工業(yè)廠房車間除塵系統(tǒng),焊接煙塵除塵,焊煙凈化設(shè)備,電焊機(jī)焊煙凈化器,大型焊接煙塵凈化器,焊接車間在對工件焊接加工時會產(chǎn)生大量的焊接煙氣,焊接煙氣中有少量粉塵需要凈化后才能排放出去,一到二個焊接工位可以使用移動式焊煙凈化器凈化處理,車間內(nèi)多個工位的,需要做集中式焊煙凈化除塵系統(tǒng),配置靈活,參數(shù)多變,根據(jù)用戶的工況量身定做,下面為大家介紹一下焊煙凈化除塵器系統(tǒng)的組成和原理

Industrial workshop dust removal system, welding smoke dust removal, welding smoke purification equipment, electric welding machine welding smoke purifier, large welding smoke purifier, welding workshop produces a large amount of welding smoke during welding and processing of workpieces. A small amount of dust in the welding smoke needs to be purified before it can be discharged. One to two welding stations can use mobile welding smoke purifiers for purification treatment, and there are multiple stations in the workshop, We need to develop a centralized welding fume purification and dust removal system with flexible configuration and variable parameters, tailored to the user's working conditions. Below, we will introduce the composition and principle of the welding fume purification and dust removal system

焊煙凈化除塵器系統(tǒng)是由除塵器,風(fēng)機(jī),管道,吸氣臂(吸塵罩),排放煙囪等組成。用于焊接煙氣凈化的除塵器可采用兩種,一種為脈沖濾筒除塵器,一種為脈沖布袋除塵器。

The welding fume purification dust collector system is composed of a dust collector, fan, pipeline, suction arm (dust hood), discharge chimney, etc. There are two types of dust collectors used for welding flue gas purification, one is pulse filter cartridge dust collector and the other is pulse bag dust collector.

脈沖濾筒除塵器采用濾筒來對焊煙進(jìn)行吸附和過濾,濾筒表面折成褶,布置密度大,可以對細(xì)微粉塵有很好的凈化效果。采用脈沖清灰,同體積除塵器過濾面積相對較大,過濾風(fēng)速較小,阻力不大。濾筒的安裝方式可做成豎插式和斜插式(沉降式)兩種。

The pulse filter cartridge dust collector uses a filter cartridge to adsorb and filter welding smoke. The surface of the filter cartridge is folded and arranged with high density, which can have a good purification effect on fine dust. Using pulse cleaning, the same volume dust collector has a relatively large filtration area, low filtration wind speed, and low resistance. The installation method of the filter cartridge can be made into two types: vertical insertion and oblique insertion (settlement type).

脈沖布袋除塵器采用除塵布袋來對粉塵進(jìn)行過濾和吸附,除塵布袋的材質(zhì)很多種,可以滿足多種工況的除塵需求,同等過濾面積的,要比濾筒除塵器外形大一些,高度高一些。和濾筒除塵器一樣采用高壓脈沖清灰,可以有效地對含塵氣體過濾吸附和達(dá)標(biāo)排放。

Pulse bag dust collector uses dust removal bags to filter and adsorb dust. There are many types of dust removal bag materials that can meet the dust removal needs of various working conditions. For the same filtering area, it is larger in appearance and higher in height than the filter cartridge dust collector. Like the filter cartridge dust collector, high-pressure pulse dust cleaning can effectively filter, adsorb, and discharge dust containing gases up to standard.

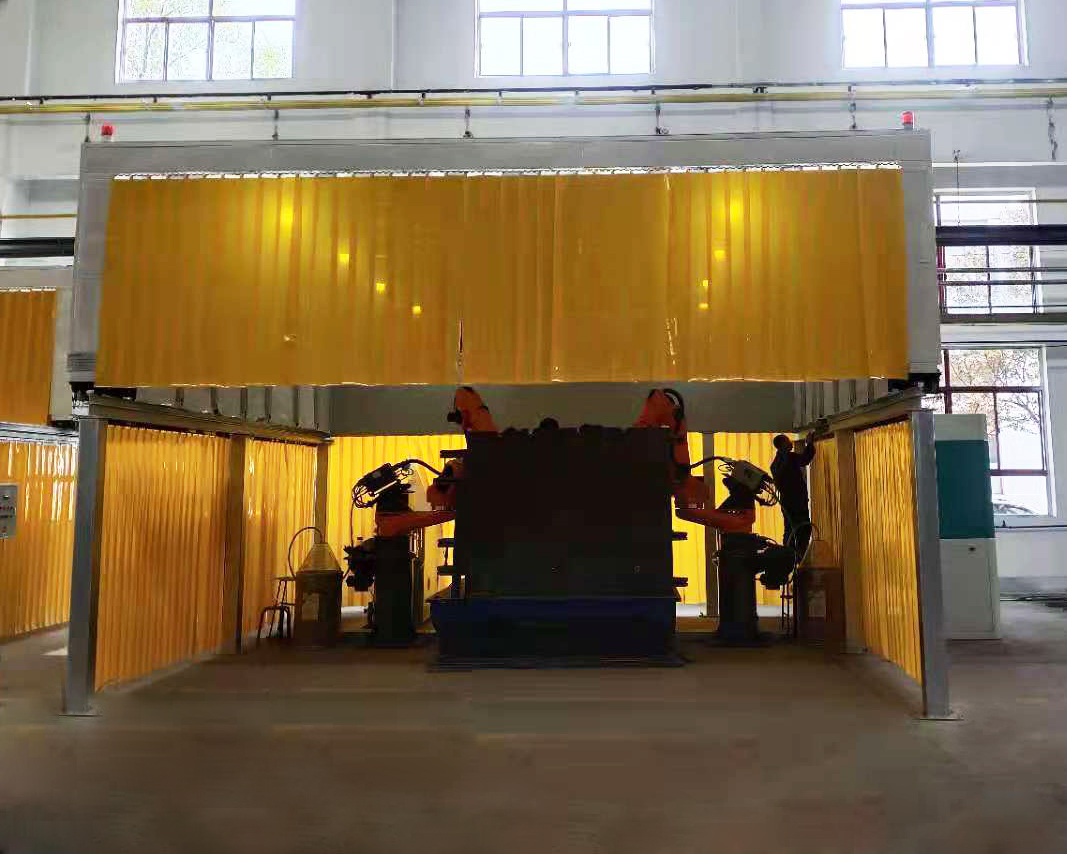

車間焊煙凈化的主管道要和除塵器、風(fēng)機(jī)的型號參數(shù)匹配,材質(zhì)可以采用碳鋼管和鍍鋅管兩種,在車間上方或者車間墻上布置主管道,然后再分支到每個工位,焊接小工件的用吸氣臂就可以,吸氣臂可以任意方向活動,非常方便,如果焊接大工件,則需要安裝一個吸塵罩,這樣可以有效的把焊煙通過吸塵罩,管道,引到除塵器進(jìn)行過濾凈化。

The main pipeline for welding smoke purification in the workshop should match the model parameters of the dust collector and fan. The materials can be carbon steel pipes and galvanized pipes. The main pipeline should be arranged above the workshop or on the workshop wall, and then branched to each workstation. For welding small workpieces, the suction arm can be used, and the suction arm can move in any direction, which is very convenient. If welding large workpieces, a vacuum hood needs to be installed, This can effectively introduce welding smoke through the vacuum hood, pipeline, and dust collector for filtration and purification.

脈沖濾筒除塵器和脈沖布袋除塵器的工作原理一樣;含塵氣體進(jìn)入除塵器灰斗后,由于氣流端面突然擴(kuò)大,氣流中一部分顆粒粗大的塵粒在重力和慣性力作用下沉降下來,粒度細(xì)、密度小的塵粒進(jìn)入過濾室后,通過布朗擴(kuò)散和篩濾等綜合效應(yīng),使粉塵沉積在濾料表面,凈化后的氣體進(jìn)入凈氣室由排氣管經(jīng)風(fēng)機(jī)排出。

The working principle of pulse filter cartridge dust collector is the same as that of pulse bag dust collector; After the dust containing gas enters the dust hopper of the dust collector, due to the sudden expansion of the airflow end face, a portion of the coarse dust particles in the airflow settle under the action of gravity and inertia force. After the fine and small density dust particles enter the filter chamber, they deposit on the surface of the filter material through comprehensive effects such as Brownian diffusion and screening. The purified gas enters the purification chamber and is discharged by the exhaust pipe through the fan.

除塵器的阻力隨濾料表面粉塵層厚度的增加而增大,阻力達(dá)到某一限定值時,清灰系統(tǒng)氣動,進(jìn)行清灰,此時脈沖控制儀控制脈沖閥的啟閉,當(dāng)脈沖閥開啟時,氣包內(nèi)的壓縮空氣通過脈沖閥經(jīng)噴吹管上的小孔噴射出一股高速、高壓的引射氣流,從而形成一股相當(dāng)于引射氣流體積1-2倍的誘導(dǎo)氣流,一同進(jìn)入除塵布袋或濾筒內(nèi),使之出現(xiàn)瞬間正壓并產(chǎn)生鼓脹和微動;沉積在濾料上的粉塵脫落,掉入灰斗內(nèi),灰斗內(nèi)的粉塵通過卸灰閥,連續(xù)排出。

The resistance of the dust collector increases with the increase of the thickness of the dust layer on the surface of the filter material. When the resistance reaches a certain limit value, the dust cleaning system is pneumatically operated to clean the dust. At this time, the pulse control instrument controls the opening and closing of the pulse valve. When the pulse valve is opened, the compressed air in the air bag sprays out a high-speed and high-pressure jet airflow through the small hole on the blowing pipe through the pulse valve, forming an induced airflow equivalent to 1-2 times the volume of the jet airflow, Enter the dust removal bag or filter cylinder together, causing an instant positive pressure and causing bulging and micro movement; The dust deposited on the filter material falls off and falls into the ash hopper. The dust inside the hopper is continuously discharged through the ash discharge valve.

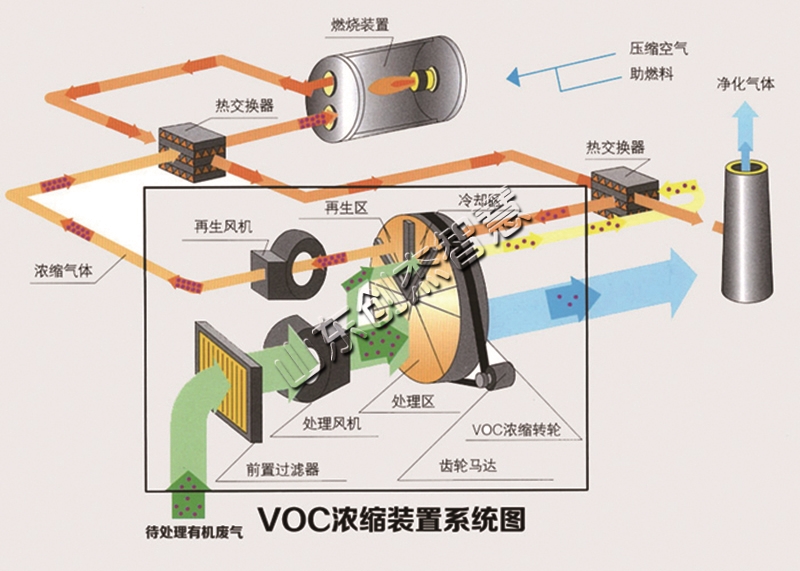

上一篇:自動噴漆設(shè)備的使用特點及分類介紹

下一篇:沸石轉(zhuǎn)輪廢氣處理標(biāo)準(zhǔn)流程

魯公網(wǎng)安備 37142502000144號

魯公網(wǎng)安備 37142502000144號